QUALITY ASSURANCE

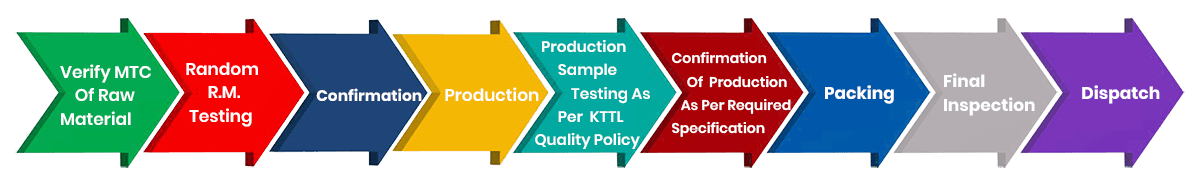

KTTL – QUALITY ASSURANCE:

The continuous monitoring of raw materials, production and products

All incoming raw materials, fibres, needed for the production of our geosynthetics, are subject to a strict material analysis. Acceptance of test certificates, submitted by base material suppliers, are reviewed and qualified in accordance with our product specific protocols.

During production of all geosynthetics, our quality assurance measures are performed. To ensure personnel effectiveness, the quality assurance staff is assigned to a separate and autonomous division from the production division.

These quality assurance measures are conducted for all of our products according to the current standards and guidelines in effect at that time. This continuous manufacturing quality assurance guarantees product performance characteristics and enables complete documentation from the raw material to the final product.

KTTL Geosynthetics also undergo Internal auditing quality process checks that are typically performed twice a year. The properties of the geosynthetic products are tested and documented in detail, including the notation of production processes, the type and extent of the manufacturing quality assurance.

Project specific product properties testing by Third Party

In special cases, Third Party testing to be done to evaluate our geosynthics products performance and to certify the test results. This testing is in addition to and completes the manufacturing quality process checks carried out on the raw materials as well as the finished products.

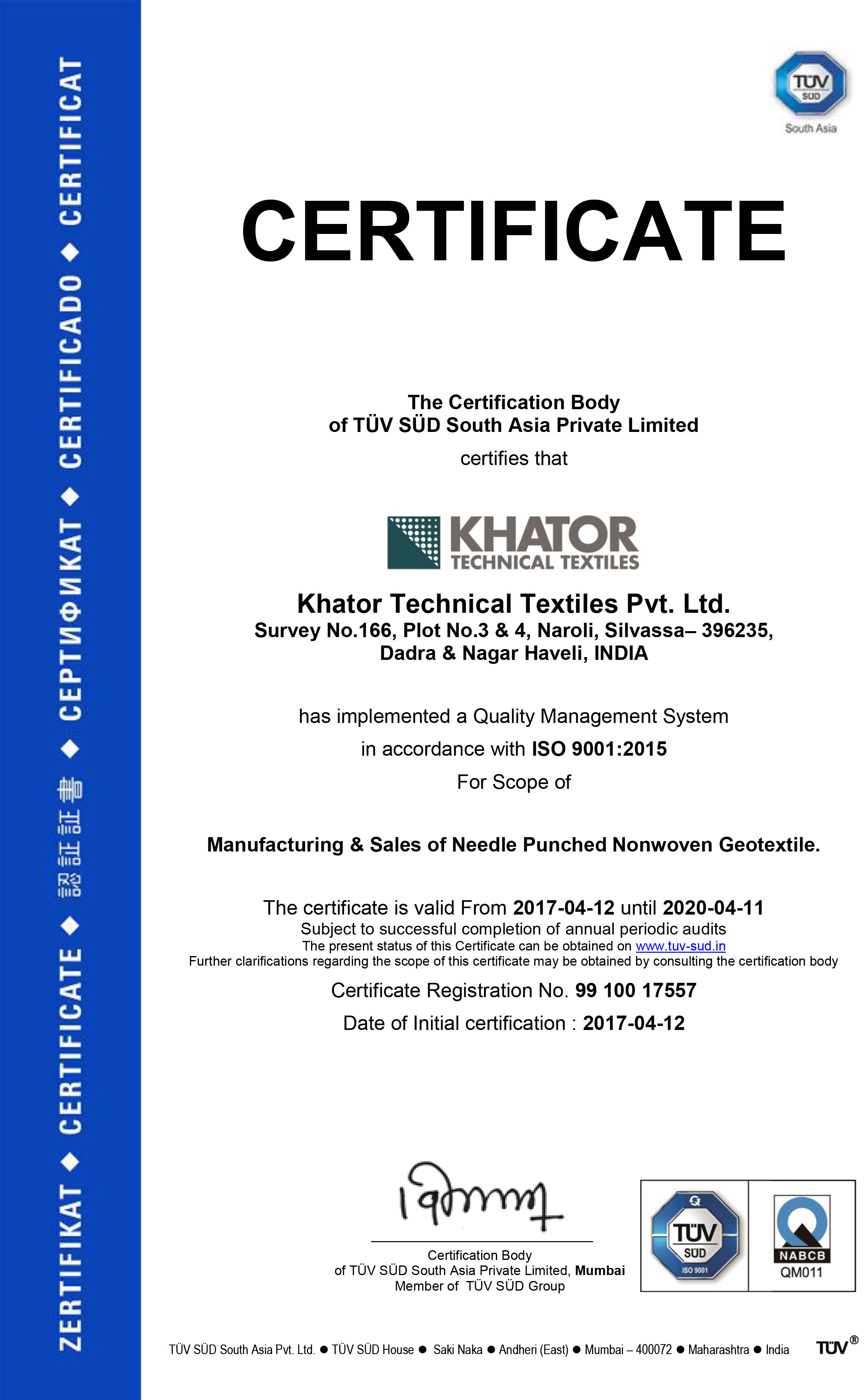

Quality management according to ISO 9001:2015

Since April-2017, the geosynthetics development, production, sales and geotechnical engineering divisions of KTTL has been certified according to ISO 9001:2015. This certification is regularly validated by scheduled audits.

With the aid of this integrated quality management system, the requirements of the customer and/or the projects are understood and fulfilled. While we continually strive to improve the quality level of our existing products and services, a high quality service is guaranteed by our ISO 9001:2015 standards.

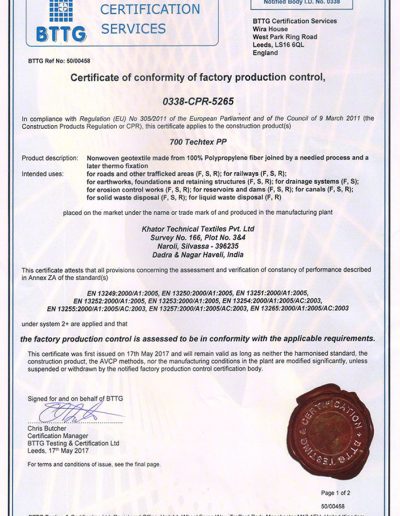

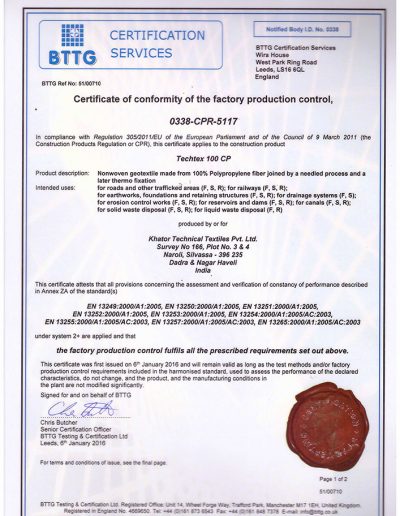

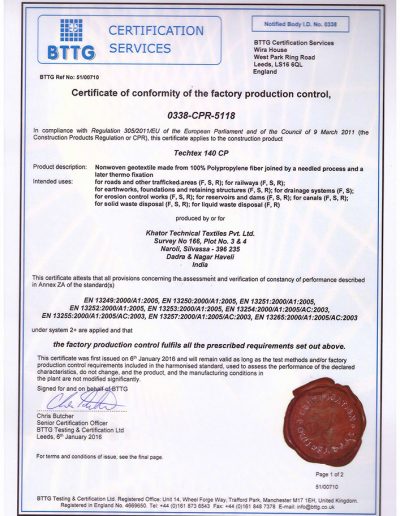

Compulsory CE-marking

The CE marking certifies that a product corresponds to the product specific European guidelines for specific applications and functions (separation, filtration, reinforcement, sealing, protection and drainage). KTTL has taken all necessary steps to put into effect the compulsory CE-marking.

Techtex 100 CP

Techtex 140 CP