Geotextile Fabric for Waterproofing

Geotextile fabric for waterproofing is typically made from a woven or non-woven polypropylene material and is available in a variety of widths and lengths. Geotextile fabric for waterproofing can be used for a variety of applications, such as roofing, underlayment, wall wraps, and foundation wrapping. The durability, flexibility, and easy installation of geotextile fabric make it an ideal choice for proofing against water damage. When it comes to product details, we can offer Nonwoven Geotextile used for waterproofing purposes. Nonwoven Geotextile purposes are offered from 80 GSM to 1000 GSM as per customer's requirement. Woven geotextiles, known for their high load capacity and tensile strength, are mainly impermeable and they are ideal for stabilization and reinforcement applications.

Benefits of Using Geotextile Fabric for Waterproofing

1. Waterproofing:

Geotextile fabric acts as a robust barrier against water penetration, preventing water from reaching sensitive areas or structures. Its tightly woven, non-porous nature effectively blocks water seepage, safeguarding basements, crawl spaces, and other vulnerable areas from water damage. This impervious layer protects foundations, roofs, and other structural elements from the detrimental effects of moisture, reducing the risk of mold growth, structural degradation, and costly repairs. Geotextile fabric ensures long-lasting waterproofing by offering superior resistance to degradation from chemicals, UV radiation, and biological factors, unlike traditional waterproofing materials like asphalt or concrete.

2. Drainage:

Geotextile fabric facilitates efficient drainage by enabling water to flow through its permeable structure. It prevents waterlogging and saturation, promoting soil stability and mitigating the risk of erosion and landslides. This drainage capability is particularly crucial for landscaping projects, green roofs, and embankments, where excess water can compromise the integrity of the soil and landscaping elements. By allowing for controlled drainage, geotextile fabric helps maintain a balanced water content in the soil, benefitting plant growth and promoting healthy root development in landscaping applications.

3. Filtration:

Geotextile fabric acts as an effective filter, trapping soil particles and debris, preventing them from clogging drainage systems and contaminating water sources. This filtration function maintains the smooth passage of water, ensuring drainage systems function seamlessly and efficiently, and protecting sensitive water sources from contamination. The filtration capability of geotextile fabric plays a crucial role in preserving water quality in ponds, lakes, and other freshwater bodies, contributing to a healthy aquatic environment.

4. Separation:

Geotextile fabric acts as a distinction layer between different types of soil or materials, preventing them from intermixing and compromising the integrity of the structure. This separation ensures that each layer functions optimally, preventing fine-grained soil from migrating into coarser materials, which can negatively impact drainage and stability. By maintaining the distinctness of different construction elements, like retaining walls, embankments, and foundations, geotextile fabric safeguards the overall structural integrity and prevents interlayer issues.

5. Reinforcement:

Geotextile fabric provides reinforcement for soil and other substrates, enhancing their load-bearing capacity and stability. Its tensile strength and resistance to deformation help distribute stress evenly, strengthening structures like retaining walls, embankments, and slopes, and preventing soil movement or failure.

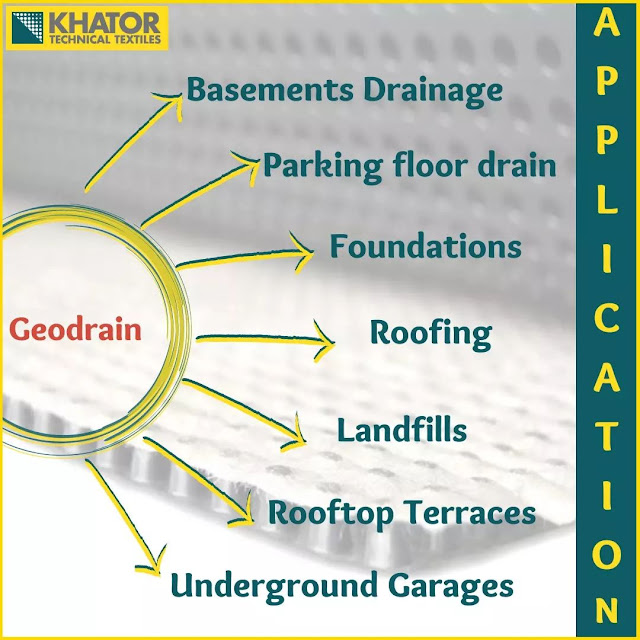

Applications of Geotextile Fabric for Waterproofing

1. Retaining Walls

Over time, small cracks and joints can form in retaining walls allowing water seepage. This moisture buildup causes corrosion and freezing expansion damage. Lining the back-side with geotextile fabrics creates a highly puncture and tear resistant barrier curtailing infiltration through walls. The fabrics remain durable despite soil movements and chemical exposure.

2. Bridge Abutments

The interface between bridge abutments and approaching embankments sees perpetual small alignment shifts from vibration and seismic activity. Geotextile sheets establish reliable moisture barriers across these interfaces mitigating erosion and settlement risks. Robust construction minimizes deterioration along the permeable and moving structural junctions.

3. Dams and Levees

As essential containment infrastructure, earth dams and concrete levees experience immense hydrostatic saturation persistence, imposing massive barrier durability demands. Both woven and high strength non-woven geotextiles supply robust water barriers protecting vulnerable structural joints and penetrations. Careful seaming and anchoring preserves multi-decade resilience.

4. Culverts

During flooding events, non-woven geotextiles around culverts provide filtration allowing rapid water percolation into surrounding soils. This relieves surface ponding stresses while avoiding pipe collapse or surrounding soil washout. The added drainage capacity limits damage potential.

5. Landfill Liners

Strict EPA regulations demand landfill runoff containment preventing groundwater table contamination as waste gradually decomposes over decades. While primary liners assume the majority of chemical resistance burden, robust non-woven geotextile drainage layers provide an added defense managing moisture safely to collection ponds.

6. Underground Structures

Across transportation tunnels, underground parking structures and subsurface detention ponds vulnerable to water migration risks, geotextile layers introduce both drainage and waterproofing redundancies managing seepage through segment joints, drain pipes or foundation cracks.

7. Foundations

In the world of foundations, geotextile fabric plays a crucial role in ensuring a dry and protected environment. It is strategically placed behind foundation walls to act as an impermeable barrier, preventing water from seeping into basements, crawl spaces, and other subterranean areas. By effectively blocking water penetration, geotextile fabric safeguards foundations from water damage, mold growth, and structural deterioration. Additionally, geotextile fabric is commonly used for foundation reinforcement, providing added strength and stability to the structure.

8. Roofs

Geotextile fabric extends its protective barrier to the rooftops, providing a reliable shield against water intrusion. It is incorporated into roofing systems, forming a critical layer beneath the roof membrane. This layer effectively prevents water from penetrating the membrane, safeguarding the interior of the building from leaks and moisture damage. Geotextile fabric's durability and resistance to harsh weather conditions ensure long-lasting protection for roofs.

9. Landscape Drainage

Geotextile fabric plays a pivotal role in maintaining healthy and aesthetically pleasing landscapes by ensuring proper drainage and slope protection. It is used as a liner in landscape drainage systems, effectively preventing waterlogging, erosion, and slope instability. By facilitating the smooth flow of water away from landscaped areas and providing protection against slope failure, geotextile fabric protects plants and structures from water damage, preserving the integrity and beauty of the landscape.

10. Pond and Lake Liners

In the realm of aquatic ecosystems, geotextile fabric serves as a protective liner for ponds and lakes, providing insulation against water seepage and contamination. It acts as a barrier, safeguarding the delicate balance of the aquatic environment and preventing the loss of valuable water resources. Geotextile fabric, with its unique thermal insulation properties, helps maintain the desired temperature in ponds and lakes, creating a favorable environment for aquatic life. This fabric is also effective in protecting ponds and lakes from potential contaminants in the surrounding soil, ensuring the purity of the water. By incorporating geotextile fabric as a liner, ponds and lakes can benefit from enhanced insulation, promoting the overall health and sustainability of the aquatic ecosystem.

How to Choosing the Right Geotextile Fabric for Waterproofing

1. Understand the Application Requirements

Begin by understanding the specific requirements of your waterproofing application. Consider factors such as the type of structure, the location, the soil conditions, and the expected water pressure. This will help you narrow down the options and identify the most suitable geotextile fabric.

2. Evaluate Key Properties

- Permeability: The ability of the fabric to allow water to pass through. Choose a highly permeable fabric for applications requiring rapid drainage and a less permeable fabric for applications where some water retention is desired.

- Strength: The ability of the fabric to withstand the expected loads and stresses. Consider the weight of the soil, hydrostatic pressure, and any potential dynamic forces that the fabric may encounter.

- Durability: The ability of the fabric to resist degradation from ultraviolet radiation, chemicals, and biological factors. Choose a fabric that is suitable for the environmental conditions it will be exposed to.

- Compatibility: The compatibility of the fabric with the type of soil it will be in contact with. Some fabrics are designed for specific soil types, such as clay or sandy soils.

3. Consider Additional Factors

- Cost: Geotextile fabrics come in a wide range of prices. Evaluate the cost-effectiveness of the fabric for your specific application.

- Manufacturer Reputation: Choose a geotextile fabric from a reputable manufacturer with a proven track record of producing high-quality products.

- Certifications: Check if the geotextile fabric meets any relevant industry standards or certifications. This ensures the fabric has been tested and meets certain performance criteria.

4. Sample Testing

Consider requesting samples of different geotextile fabrics to evaluate their properties and suitability for your project. This can help you make an informed decision based on visual inspection and physical testing. Examples of Geotextile Fabric Selection:

- Roofing Application: Choose a geotextile fabric with high tensile strength to withstand the weight of the roof assembly and provide long-term protection against water infiltration.

- Foundation Waterproofing: Select a geotextile fabric with low permeability to prevent water penetration into the foundation walls and crawl spaces.

Related Resources

If you found this overview on geotextile fabrics for waterproofing useful, make sure to check out these other in-depth posts on geosynthetics applications:

- Geosynthetics and Mining Applications - Learn how geotextile fabrics are used extensively in the mining industry for filtration, drainage, separation and stabilization.

- Guide to Non-Woven Geotextiles - Get a comprehensive understanding about non-woven geotextile fabrics, their mechanical properties, key functions, and common applications.

These posts provide additional info on how versatile geotextile fabrics are used in civil engineering, construction, landscaping, mining, and environmental projects. Check them out for more industry knowledge and solutions using geotextiles.